Previously

In the previous cnc machine post an initial design for the CNC machine was outlined. Realising I was going to have to spend a descent amount of money making a machine the design felt a little hobbyish and perhaps not as durable as I would like. It's potential for expansion was also limited. This might sound a little nuts but bear with me. Using the same structural components the machine could only be extended to 6m in length. Long but not long enough for some of my ideas.

New Idea

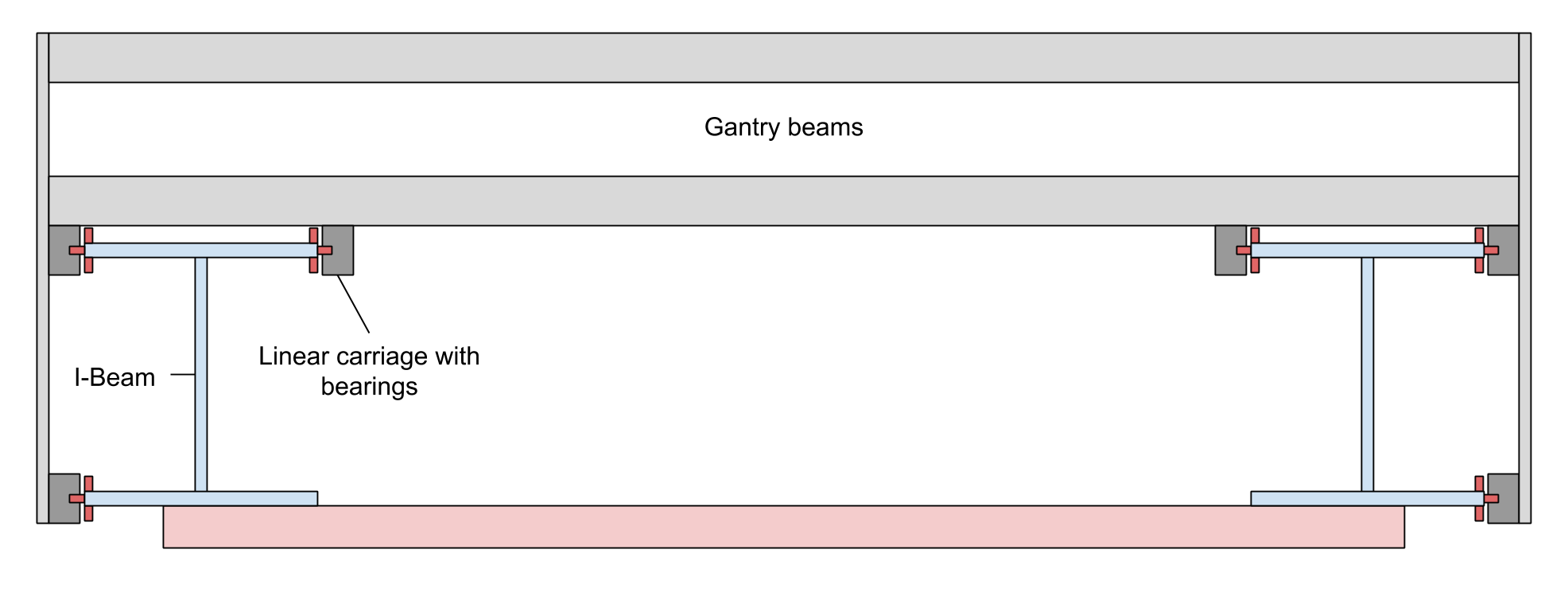

The main change is to make the structure and linear rail the same thing, an I-Beam. A simplified example is shown below.

Why? An I-Beam is extremely sturdy and strong, great for a robust, industrial like machine. They can be purchased in up to 18m long!!! The idea is instead of having multiple machines why not have multiple gantries (a bit of future proofing here). Also I want to build a nice big yacht one day and a house, making big things requires big machine :) From a business angle it makes sense as well. If I want to start offering machining services a machine with multiple gantries is much more flexible than multiple machines:

- Multiple gantries are cheaper than multiple machines.

- Multiple jobs can be done at once, prices depended on the length of machine and time used.

- Each gantry can have access to the full length if needed.

- Less machine space is wasted for small jobs as other gantries can be used on the remaining space (a nesting problem).

One problem associated with using an I-Beam is the surface smoothness and consistency. Hopefully with priming and painting it will be smooth enough for the carriages.

New Frame

Using a 152 x 152 23kg column beam standard carriages found at cnc router parts can be used with very little modification. Cnc router parts standard pinion belt reduction system should also fit with light modification. If not it can be mounted on the top rather than the bottom. The belt reduction system requires the stepper mount to have a 1/4in shaft! To run more powerful nema34s a larger beam will be needed or it will have to be mounted on the top.