A lot of my projects require some sort of complex curvature which inevitably gets simplified due to a lack of machining resources. Considering this I have decided to have a crack at building my own CNC machine. Being me I wanted to make it from scratch so a bit of research was in order.

Existing Machines

A few 'mainstream' machines that have caught my eye so far:

- Shapeoko 3

- X-Carve

- Openbuilds c-beam system

- OX machine

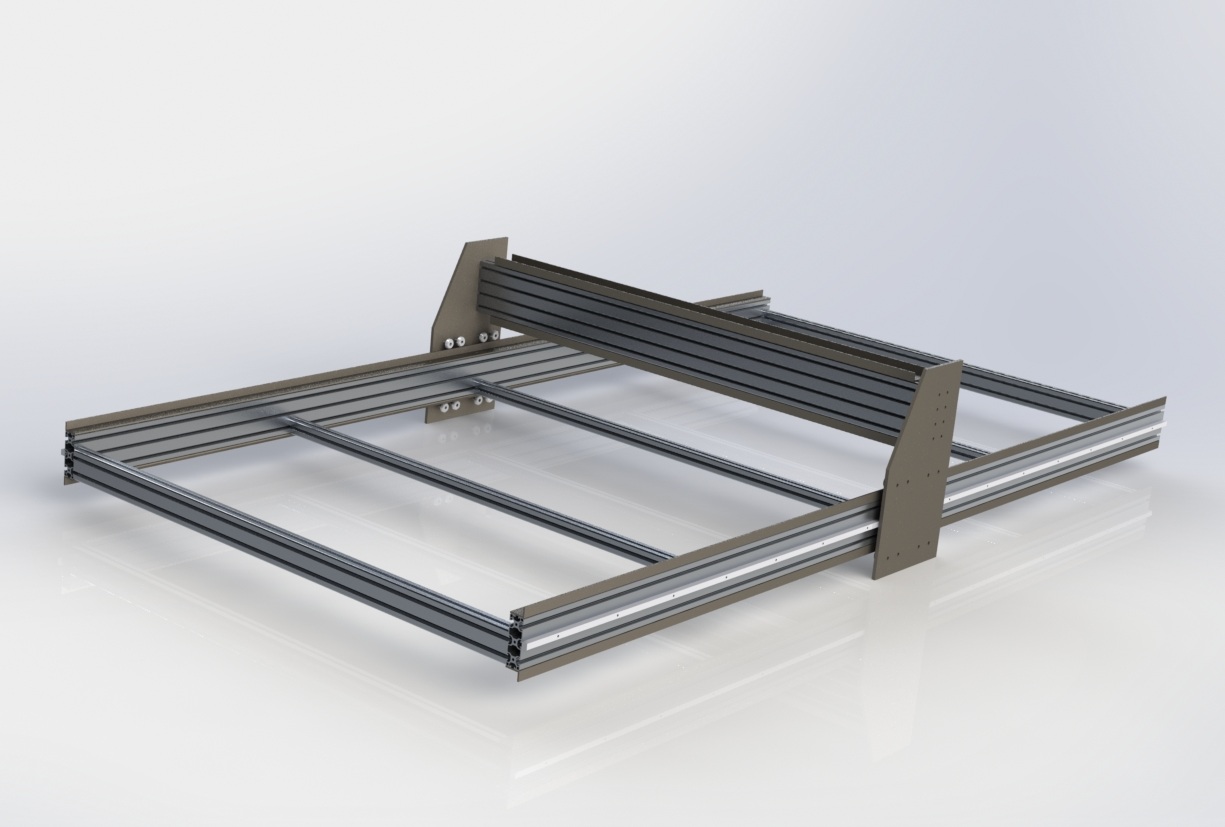

Building the frame

The Shapeoko 3 frame looks the strongest and is beautifully elegengant compared to the usual aluminium T-slot extrusion. It is however a custom extrusion which means the machine cannot be easily expanded from the original size. The x carve uses standard T-slot extrusion which seems okay for the standard machine sizes. The gantry plates do not allow the size of the extrusions to be changed (2 20 x 40) which means that expanding the machine is also a problem. The original extrusion size cannot handle large distances without flex.

References