Published: 23-01-2015

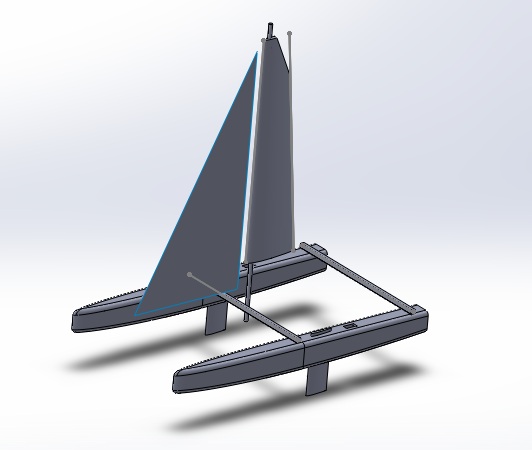

This project is based around designing and building a beach catamaran. This is partly for fun but also as a test bed for future bigger boat designs.

Some of the designers/manufacturers I have looked at for inspiration:

- Chris White - Especially his Mastfoil idea

- Kurt Hughes

- Derek Kelsall

- Gunboat

- Le Breton Yachts

- Shuttleworth Yachts

- Nigel Irens

Something Different

One of the things I wanted to incorporate was the use of solid wings or foils over soft sails. This would theoretically improve performance while reducing the number of control lines needed. Although a full move to solid wings might be fine in a small boat/dingy it is not as practical in a large cruising boat. Here a combination of soft sails and solid wings can be used. This requires the ability to manufacture fairly large wings cheaply which is something I am trying to accomplish in my wings project.

Manufacturing

Manufacturing poses the biggest problem, maybe not for a 16ft design but for a scaled up 30-40ft version. I know that structurally they are very different beasts and the structure cannot simply be 'just scaled up'. However, the 16ft version must be manufactured the same way as the potential full size yacht (i.e. fully moulded, cylinder moulded, strip plank etc.)

I get fed up fairly easily when doing monotonous tasks and I don't like mess or dust. This fussiness only came about after having to hand sand and wet layup FS Bodywork, which turned out to be weeks of messiness. Hence I would like a clean manufacturing process which requires little to no finishing. There is only one of me and I don't plan on roping people in to do dusty, dirty and potentially dangerous jobs. Resin infusion fits the brief whether carried out on a flat surface or a mould.